Errore di furmatu di email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

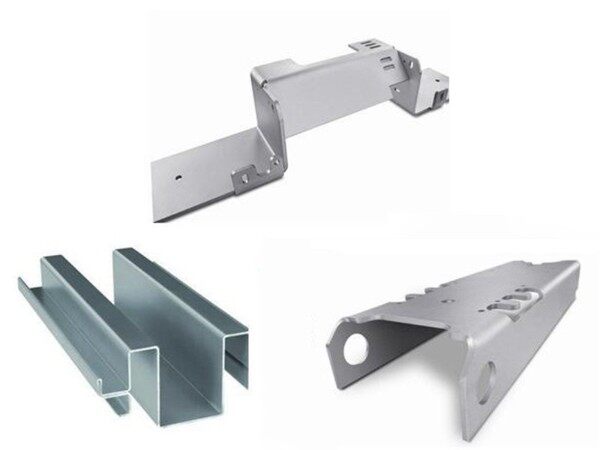

Four Processes of Sheet Metal Processing

Importance of sheet metal processing technology: The processing of sheet metal is called sheet metal processing, which is an important process of sheet metal product forming. Sheet metal processing includes traditional cutting, blanking, bending forming, and other methods and process parameters, as well as new stamping technology and new process.

Traditional sheet metal processing includes four main processes: cutting, punching/cutting, folding, and welding, while the latest four major sheet metal processing processes are: exciting, punching, folding, and welding.

The main processes of sheet metal processing are also upgraded layer by layer with time.

The latest processes are introduced below.

Laser cutting

Laser cutting is the main equipment for blanking in sheet metal processing. It has the advantages of fast processing speed, high precision, short cycle (no need to open a mold), and can process various shapes. It is the main processing method of sheet metal processing and blanking.

Punching

The parts processed by sheet metal can't only have a flat plate shape, but need punching convex hull, sprouting, punching shutter (a kind of vent), bridge, buckle, etc. All need to be processed by punching. Punching is not the previous punching machine, but a CNC punching machine. It can install dozens of molds, which is programmable and fast. It can also assist the laser cutting machine in blanking.

Fold

Compared with the past, it's just that the equipment has been updated. There are CNC bending machines, bending centers (manipulator-assisted bending), CNC folding machines, etc.

Welding

Compared with the past, it is only an increase in equipment. Argon arc welding, carbon dioxide gas shielded welding, and welding robots for thin plate welding are added.

Difference between sheet metal processing and precision sheet metal processing

The range of sheet metal processing is relatively large, and all products with metal forming can be collectively referred to as sheet metal parts.

Among them, sheet metal is divided into general sheet metal and precision sheet metal, which are mainly different in technology. Ordinary sheet metal uses traditional processing equipment, such as ordinary punch, corner machine, etc. to achieve the shape, it is often processed for batch products, and the accuracy cannot be guaranteed, and some complex processes are difficult to achieve.

Advantages of precision sheet metal processing:

Precision sheet metal processing is suitable for processing large and small batches of products, with the characteristics of a short processing cycle, high precision, good uniformity, and so on.

Conditions for precision sheet metal processing:

The transition from ordinary sheet metal processing to precision sheet metal processing requires the following conditions: equipment upgrading, technology upgrading, management improvement, etc.

With the upgrading of the main processes and equipment of sheet metal processing, the quality of sheet metal processing products has been greatly improved, and the processing speed and response are faster. With the development of society, the sheet metal processing industry is also making progress, and its role in the new era is becoming more and more important.

We are a cnc sheet metal bending, cnc sheet metal fabrication, wax casting silver exporter supplier wholesaler, our products satisfy our customers. And we want to be your long-term partner, any interests, welcome to contact us.