Errore di furmatu di email

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

News

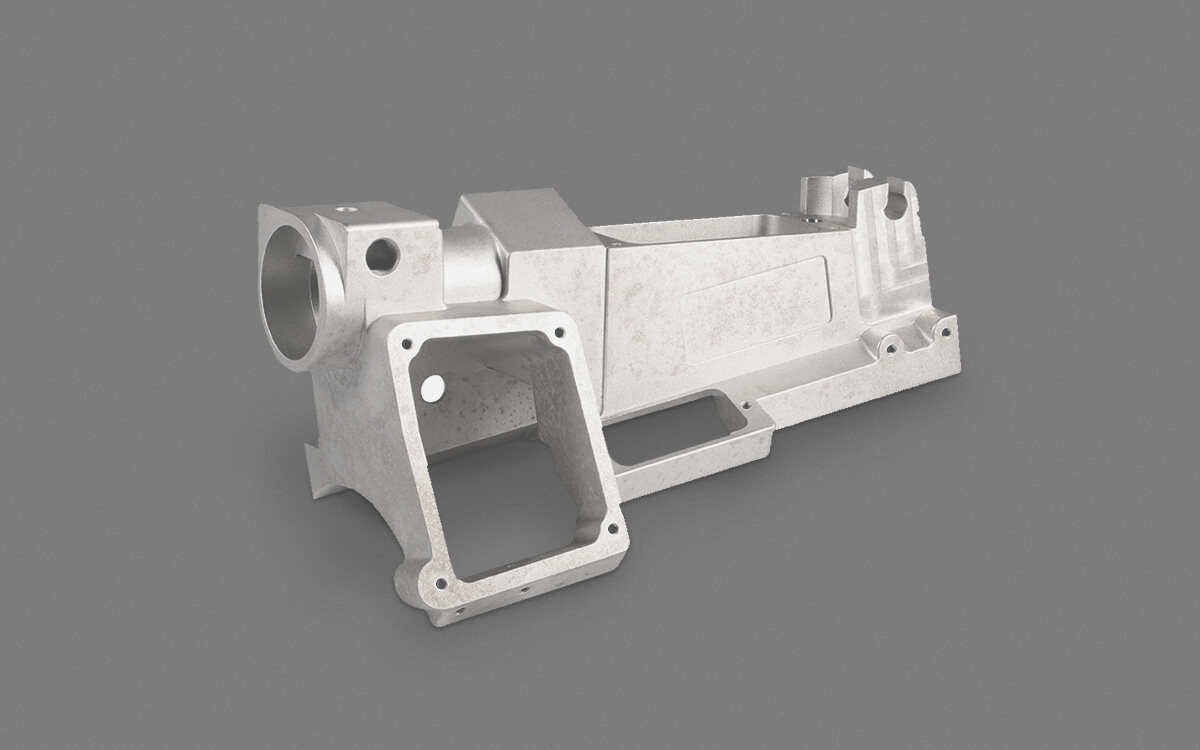

casting parts factories, manufacturer

In the consultation process of purchasing machine tool bed castings, you should try to express your requirements in advance, such as casting material, processing requirements, shape and size, weight, technical requirements, and ordering quantity of castings. The normal quantity and annual demand of castings must also be clear.

Machine tool casting parts include ordinary casting, resin sand casting, precision casting, and so on. The price of different casting costs is different, and the quotation is also different.

Mould

The machine tool casting foundry quotes the mold as a separate project, which is a one-time cost. After payment, the mold belongs to the customer. Molds include wood molds and aluminum molds. Generally, a single piece or several pieces can be produced by wood mold, and wood mold can also be used for large products. Batch aluminum mold production.

Wood mold is easy to be damaged, deformed, and difficult to preserve in the production process, but the cost is low and can save the cost. The deformation coefficient of aluminum mold is small, which can ensure the dimensional accuracy of products, the machining allowance can be lower than that of wood mold, and the reusability is good.

Casting blank

The process of molding and pouring into the blank of bed casting. The mold includes product appearance and pouring system. The pouring system includes sprue, transverse sprue, inner sprue, and riser. The pouring and pouring system is the part to be removed in the process of product and cleaning, and it is used for waste treatment. The weight of the casting system of steel castings is generally 70-150% of the weight of the product blank. Gray iron is 20-35%. Ductile iron is 20-40%.

In addition to these additional costs, bed castings will also produce waste products due to other reasons, such as shrinkage, porosity, porosity, etc. Generally, the scrap rate is controlled at about 7%, which are the direct cost factors in casting production.

Product processing

Part drawings are the main data. Product processing is carried out according to the drawings. The drawing shall find out the part name, tolerance, surface roughness, key dimensions, machining basis, inspection requirements, heat treatment conditions, etc. The processing method can be determined according to the technical requirements. Product processing also has cost loss: processing waste and waste caused by casting exposed after processing.

In addition, the machine tool casting parts manufacturer will determine whether to open aluminum mold or wood mold according to the customer's requirements for the number and technology of platforms. The prices of wood mold and aluminum mold are also different. The quantity is different, and the processing technology used is also different. The price of a single piece and batch varies greatly. The batch can be used with a CNC lathe, and the cost is naturally reduced. Knowing the above information, I believe the quotation given to you by the supplier will be very reasonable and accurate.

Searching for casting parts factories in China, you can get high-quality products at a nice price.